The Last Gasp Of Open Wire Insulators

Reprinted from "Crown Jewels of the Wire", June 1996, page 12

Gerald S. Schrage

Chief, Southeast Engineering Branch

Rural Utilities Service

Even though he didn’t realize it, President Harry S. Truman began the

demise of the use of open wire (pin type) glass insulators in telephone plant

construction in the United States on October 28, 1949. On that day, he signed

the Bill (63 Stat. 948) to amend the Rural Electrification Act to authorize the

Rural Electrification Administration (REA) , now known as the Rural Utilities

Service, to make loans for the purpose of furnishing and improving rural

telephone service.

The REA was first created by Executive Order 7037 on May 11, 1935 as part of

a general program of unemployment relief. Its task was to bring central station

electric service to farms and ranches. At that time, barely ten percent of farms

in the United States had electric service. To accomplish its mission, it helped

rural groups form Cooperatives which would build and own the lines, contract for

wholesale power, and bill its customers for electric usage. REA was the source

of financial capital which was not readily available from the private financial

markets. It made loans at the cost of money to the Federal Government. This

program was so successful that it grew to over 1000 rural Cooperatives within

ten years serving over 1.6 million rural customers.

Initially, telephone service was more widespread than electric service. This

was because telephone lines and service could be provided at less cost than

electric lines and service. It took fewer people cooperating together to build a

“farmer line” or a smaller community to make a small “Mom and Pop”

company economically feasible. However, the depression, maintenance, storms and

personnel replacements eventually wore down this base and in the 1930s fewer

farms had telephone service than each of the years before. By 1940 the low point

of 25 percent of the farms with telephone service had been reached.

Coincidentally, in that same year, the percentage of farms with electric service

(30 percent) passed the percentage of farms with telephone service. With the end

of World War II, electricity was being brought to farms and ranches through the

aid of the REA program at a rate double that of telephone service being provided

by private industry. Because of this slow progress, the RE Act was amended to

allow loans to private telephone companies and cooperatives. As a comparable

measure of its success, the telephone program in its first ten years grew to

over 700 rural telephone companies or cooperatives serving over 1.1 million

customers.

By way of this history of the origin of the REA telephone program, we come to

its role in the death of open wire telephone plant construction in the United

States. The REA telephone program was very fortunate to obtain the services of

retired members of the Bell Telephone Laboratories and other industry experts at

the time of its beginning. This cadre of highly trained engineers took upon

themselves the challenge of essentially creating a standardized rural telephone

industry. They realized they had a once in a lifetime chance to create an

industry from scratch and not be restricted to or hampered by past practices.

They wanted REA financed systems to be state-of-the-art and as forward thinking

as economically possible. As an example, they set standards such that

eight-party service would be the minimum acceptable with four-party service as

the ultimate goal. This was considered revolutionary when at the time the

accepted grade of rural service was 10 or 20-party service if at all.

To accomplish their goals, they knew they had to standardize on everything.

All rural systems must use the same parts, be assembled in the same

configurations and be built by the same construction methods, and be tested and

proven in the field. This would give them economies of scale and lower costs.

They created an REA engineering division which wrote standard specifications,

designed standard configurations, created standard constructions methods and

tested and accepted individual parts for use on these rural systems. The open

wire (pin type) glass insulator was one of many individual parts tested and

accepted for use on REA- financed construction. A group of engineers called “Committee

A” was formed to analyze the appropriateness of parts submitted by various

manufacturers for use in REA construction projects. Their function was to

determine if the part was appropriate for widespread use, to set up and monitor

a field trial of its usage, and to grant it REA “acceptance” where

appropriate.

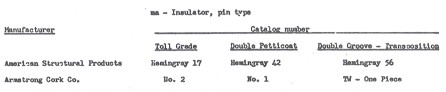

The pin type insulator was one of the items on the very first “List of

Materials” (LOM) acceptable for use in REA construction projects issued in

December, 1950. This LOM was similar to a catalog and pin type insulators were

listed as item “ma”. A copy of that page is shown as Figure 1 with six

insulators listed as acceptable. As part of the overall construction methods and

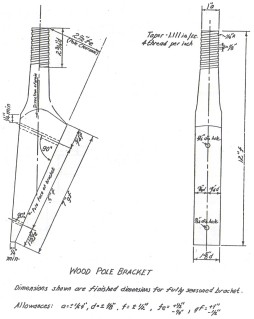

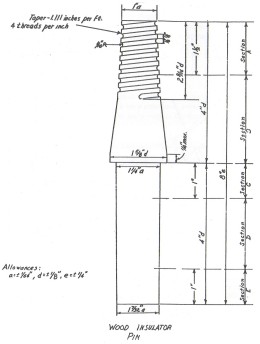

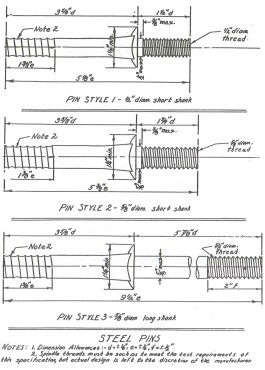

design, these REA engineers wrote numerous specifications. Of particular

interest to pin type insulator collectors, they wrote PE-4 (Specifications for

Wood Insulator Brackets), PE-5 (Specifications for Wood Insulator Pins) both of

which were published in November 1951 and (Standards for Bolt Type Steel

Communications Insulator Pins) published in December, 1952. Figures 2, 3, and 4

are drawings for brackets and pins from these publications respectively. Also,

REA published Form 511b (Specifications and Drawings for Open Wire Construction)

which all contractors had to follow in constructing the rural open wire lines.

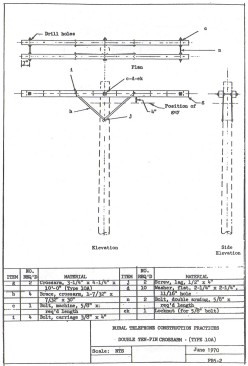

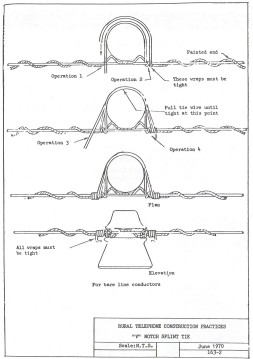

Figures 5 and 6 are typical drawings from that standard showing the construction

of a double ten-pin crossarm and a “V” notch splint tie, respectively.

As a result of these standards, millions of the pin type insulators accepted

by REA were used in rural telephone construction in the United States. Like

everything else, the pin type insulator industry experienced changes, albeit

slowly. For 23 years they remained on the REA list of materials until March,

1973 when Committee “A” voted to terminate all open wire construction by REA

financed companies or cooperatives. Insulated copper pair cable construction had

superseded open wire construction . No longer would open wire construction be

financed by REA, so rural companies ceased using pin type insulators in new

construction and used them only for maintenance of existing systems. Table 1

outlines the 23 year history of pin type insulators in the REA program.

As I said in the beginning of this article, President Truman began the demise

of the use of pin type insulators when he signed the Bill creating the Rural

Electrification Telephone program. No one else but the Federal Government could

have created REA which in turn had the clout to create a standardized open wire

construction design and similarly, had the clout to kill it. We at REA are proud

of the accomplishments of the rural telephone industry and our part in fostering

it. Today, the REA financed companies and cooperatives provide some of the most

advanced, digitally switched, single party service to over six million

customers.

Mr. Schrage is the Secretary/Treasurer of the Chesapeake Bay Insulator Club,

9274 Linden Court, Manassas, Virginia 22110

|

Table 1

Use of Pin Type Insulators

in the REA program |

| |

|

| Date |

Event

|

| 1949 |

REA telephone program created on October 28, 1949. |

| 1950 |

Initial List of Materials issued in December with American Structural

Products and Armstrong Cork Company as the first accepted manufacturers of

pin type insulators. Insulators listed as item "ma". |

| 1953 |

In February, the Hemingray #45 insulator replaced the Hemingray #42

double petticoat insulator manufactured by American Structural Products on

the List of Materials. |

| 1956 |

In July at meeting #57 of Committee "A" , Kimble Glass Company

replaced American Structural Products as the accepted manufacturer of

Hemingray # 17, 45, and 56 insulators. |

| 1957 |

In March the double petticoat insulator category (Hemingray #42, and

Armstrong # 1) was dropped from the List of Materials by vote of Committee

"A" in meeting #70. |

| 1958 |

The June issue of the List of Materials added a new category of

insulator. Added were the "double groove-carrier" type of

insulator represented by the type "TS" by Armstrong Cork Company

and the "Hemingray TS-23" by Kimble Glass Company. |

| 1962 |

In April, a note was added to the List of Materials allowing the use of

the "TW" (one piece insulator) for the "TS"

manufactured by Armstrong Cork Company in certain specific types of

construction. |

| 1970 |

A new manufacturer (H. K. Porter) was added as a supplier of toll grade

insulators. The Porter company's model number was "106932". |

| 1972 |

In January, 1972 the List of Materials was reissued and both the Kimble

Glass Company and the Armstrong Cork Company were dropped as manufacturers

of pin type insulators. I was not able to find a record of why they were

dropped but the most likely reason is that they stopped manufacturing

insulators and requested REA to remove them the List. This left H. K.

Porter as the only supplier of insulators for REA projects. |

| 1973 |

At meeting #404 of Committee" A", it was voted to eliminate

all open wire construction in the REA program. As a result, pin type

insulators were dropped completely from the List of Materials. I talked to

a senior engineer who is still with REA and he states that it was a very

emotional event as the "old-timers" at the time hated to see a

project die that served them so well. |

Figure 1

Medium Image (44 Kb)

Large Image (88 Kb)

Figure 2

Medium Image (39 Kb)

Large Image (80 Kb)

Figure 3

Medium Image (81 Kb)

Large Image (155 Kb)

Figure 4

Medium Image (61 Kb)

Large Image (124 Kb)

Figure 5

Medium Image (51 Kb)

Large Image (111 Kb)

Figure 6

|